Sludge drying and incineration integrated system

This system is the result of in-depth cooperation between AIECO and Southeast University. A variety of fluidized bed drying and incineration technologies, rotary atomization incineration technologies, and disc drying and incineration technologies are jointly designed and developed. It professionally provides a one-stop overall solution for sludge drying, sludge incineration, and sludge resource processing. The material source has low requirements for moisture content and can be directly disposed of without deep filtration, with a reduction of more than 90%. By organically combining the sludge drying and incineration systems and utilizing the waste heat inside the incineration system, there is no need to add additional auxiliary fuel. The incineration can produce uniform output, the slag can be used for brick making, with high resource utilization and ultra-clean exhaust emissions.

Processing capacity: 20t/d~1500t/d

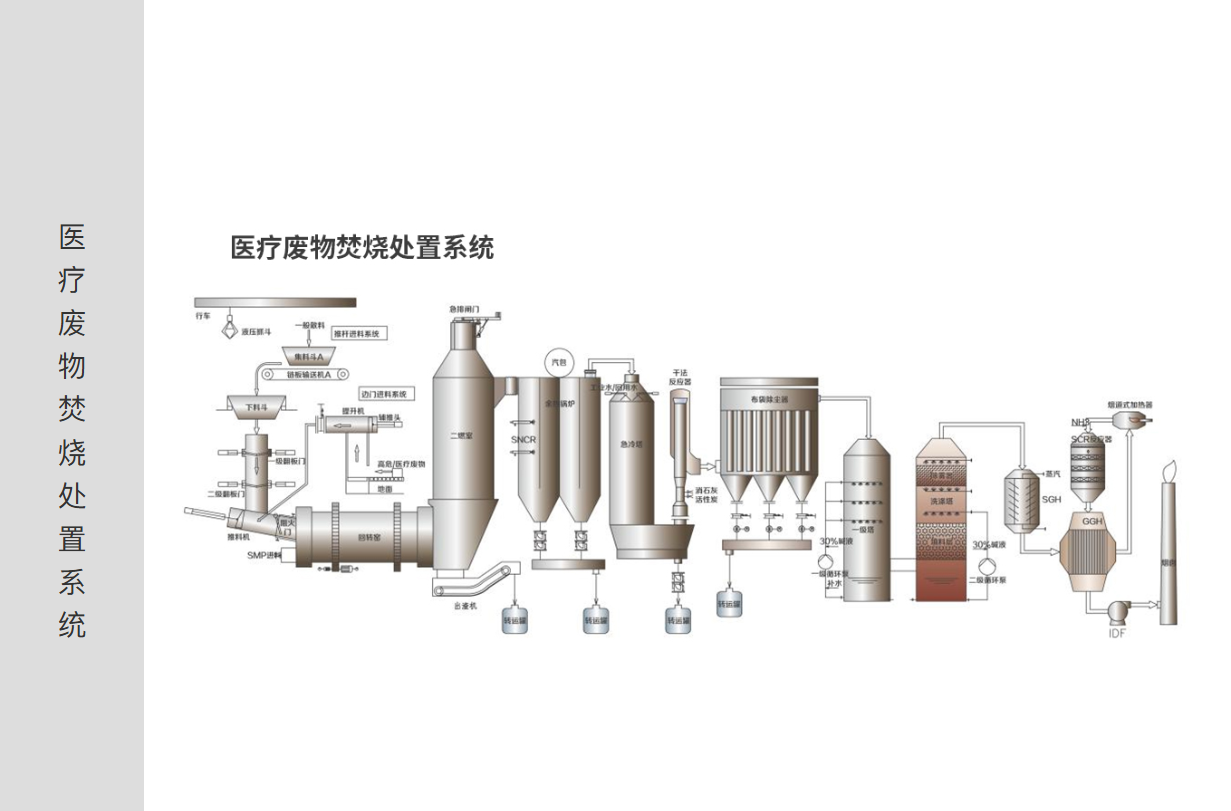

Medical incineration disposal system (medical waste incinerator)

medical incineration disposal system (medical waste incinerator) can dispose of various medical wastes and domestic garbage at the same time.

It has many advanced technologies, including fully automatic feeding system for medical waste and domestic waste, automatic cleaning of turnover barrels, mature rotary kiln system and ultra-low emission exhaust gas purification process.

Different processes are flexibly adopted according to regional emission requirements, and flue gas emissions meet and exceed European standards.

The system has a long continuous operation time, low maintenance and an annual operation rate of over 90%.

Processing capacity: 3t/d~100t/d

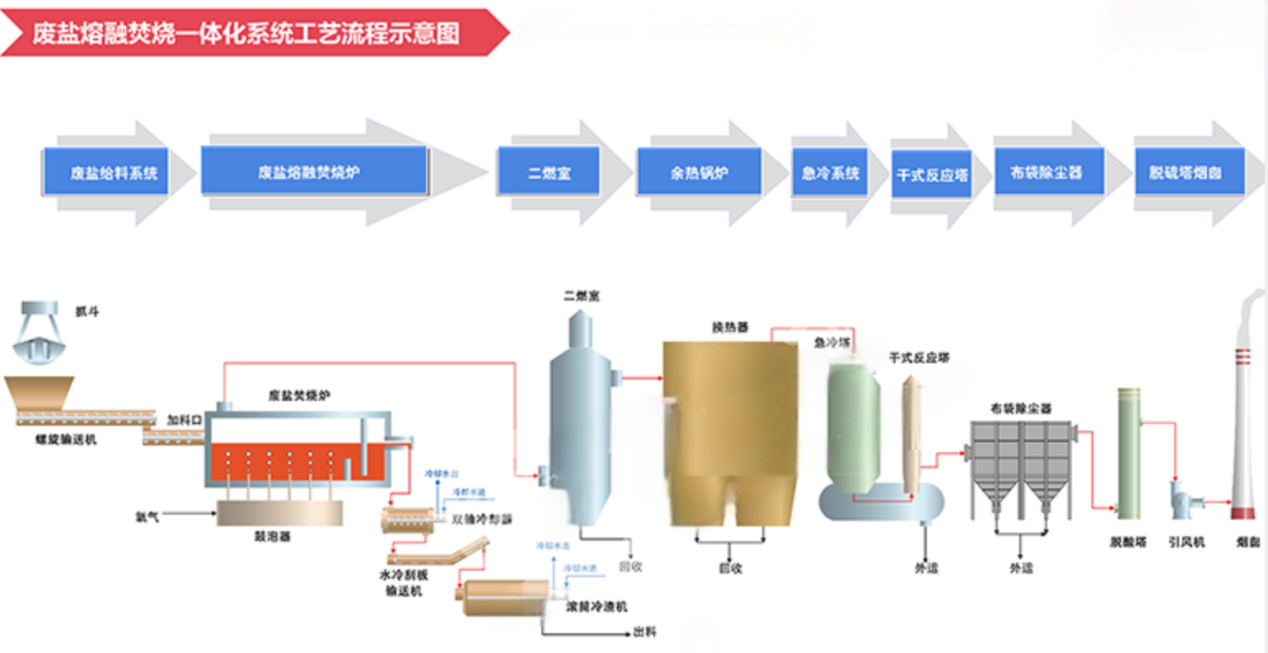

Waste salt melting incineration integrated system

The integrated waste salt melting incineration system is suitable for the incineration and disposal of hazardous solid wastes such as organic waste salt and salt slag.

The treatment process is as follows: the waste salt is melted by high-temperature radiation in the melting furnace, and the organic matter in the waste salt is burned out and discharged from the flue into the secondary combustion chamber, and continues to burn to above 1100°C before entering the exhaust gas purification system. The high-purity salt solution slowly flows to the tail and overflows from the soup outlet. After flaking, conveying and grinding, it can be sold or comprehensively utilized.

It adopts full oxygen bubbling, pure oxygen supplementation and low nitrogen combustion melting technology. The sodium chloride treated by melting purification has reached the industrial salt standard and the exhaust gas is up to standard. Provide a one-stop overall solution for the harmless disposal of waste salt.

Processing capacity: 5t/d~200t/d

Waste liquid (high salt wastewater) incinerator

Waste liquid (high-salt wastewater) incinerator is suitable for high-concentration and high-salt organic wastewater, the salt content of which can be between 1% and 30%.

According to the actual requirements of the project, automatic, semi-automatic and manual salt production is realized, and the system has a long continuous operation cycle.

The recycling of waste heat after waste liquid incineration can be fully considered and emission standards can be achieved.

It has strong combustion stability, high safety, convenient operation and maintenance, and low operating cost.